|

|

|

|

|

Contact

Us to learn more

about Schunk-Inex equipment

| Welcome

to Schunk-INEX Corporation

Schunk-INEX specializes in the manufacturing of Composite

Radiant Tubes (CRTs). Schunk-Inex CRTs consist of silicon

carbide in a silicon matrix and are made by our exclusive

patented, simple fabrication process using low- cost

abundant raw materials.

Composite radiant tubes

were put on the market in 1988 to take the place of

conventional metal alloy and mullite radiant tubes used in

heat treating furnaces around the world.

|

|

|

|

| To

Improve Your Operation and Save Money, The Choice Becomes

Obvious... |

|

|

|

|

| For

Longer Tube Life... |

|

|

|

|

|

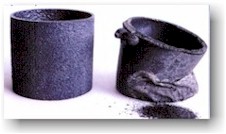

Metal

alloy radiant tubes can result in poor life due to:

- Creep

- Melt Through

- Oxidation

- Carburization

The end results are high maintenance costs and increased

downtime.

In addition to poor life, the heat flux of conventional

radiant tubes is also limited by low maximum temperature.

The Schunk-INEX Silicon/Silicon Carbide composite tube on

the left side of the adjacent image was tested for 360 hrs.

The alloy 600 tube on the right was tested for less than one

hour. |

|

|

|

Creep

Test at 1350° C (2462°F)

(Tests conducted by Hi-Tech Ceramics, Alfred, NY.) |

|

|

|

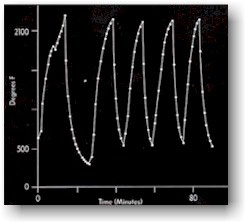

Severe Thermal

Shock Test for Silicon/Silicon Carbide

Material

Test System ..... INBZ-1001

Input ..... 150,00 BTU/HR

N.G. @ 20% XS Air

Material ..... Schunk-Inex Si-SiC

Total Cycles ..... 5

Average

Heat Rate ..... 160°F/Min.

Average

Cool Rate ..... 256°F/Min.

(Test

conducted by Pyronics Inc., Cleveland, OH.)

|

| Mullite

tubes failed in the first cycle of this test. |

|

|

|

| For

Higher Temperature Capability... |

- 2450°F Maximum

Tube Temperature

- Heat Flux: 200 BTU/hr/in^2 |

| For

Low Cost... |

- A unique dual

phase, composite material- silicon/silicon carbide,

has been specifically formulated for high

performance and low cost.

- Our innovative, patented manufacturing process

produces composite radiant tubes at a price

competitive with conventional metal tubes.

- Using Schunk-INEX CRTs lowers operating expenses:

- reduces furnace downtime

- reduces tube replacements

- reduces labor time

- reduces cycle time

- handle higher temperature work |

| Where

Other Tube Materials Fail, Schunk-INEX Composite

Radiant Tubes Are The Obvious Choice. |

|

|

|

|

|

To find out more about these systems,

please submit an information request <here>

|

|

|

|

|

|

|